Yottaasys Develops AI Driven Automatic Surface Defect Detection for Hot Rolling Metals

– Arun Pandey, CEO, Yottaasys

Manual inspection of Steel billets or casters is challenging because a person is unable to apply a consistent level of inspection all over the billets at the required throughput speed. This means defects are missed and get delivered to the customer and may have additional value-added before the defects are noticed. When this occurs the customer generally makes a claim on the company, not only for the lost tonnage, but also for the added value and associated costs. Therefore, the claims can be high and disproportionate to the value of the Bars/Rolls. To automate major aspects of quality control and automate defect detection in Billets using the latest technological advancements in Artificial Intelligence and Computer vision, NIRMAAN Powered Automatic Surface-Inspection System (NPASIA) has been developed.

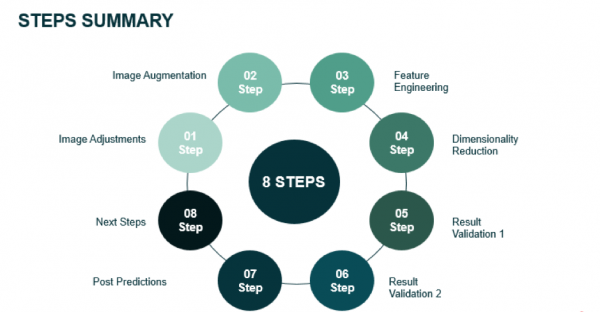

NPASIA is an online surface-quality Inspection System using its Proprietary Tool – Dhrishti that helps address this challenge by detecting and automatically classifying all surface defects visible on the strip: inclusions, mechanical damage, scales, repeating defects such as roll marks and dents, as well as coating defects and other imperfections. NPASIA – Dhrishti is available across flat-product rolling and processing applications: This can be implemented across hot mills, pickling lines, cold mills, continuous annealing lines, metallic coating lines, hot-dip galvanizing lines, electrolytic galvanizing and tinning lines, color-coating lines, and stainless-steel lines.

“NPASIA is a big AI based disruption in Automating QA and Inspection for Hot Rolling Metals, the solution shows tremendous possibilities of AI automating core business processes and increasing customer delight.” – Soham Shah, Angel Investor

About

Yottaasys is all about data and insights based on data. We have productized data sciences in our product Decision Sciences Factor(DSF) which has been reformed into NIRMAAN. Nirmaan is an AI platform with the two-fold objective of digitizing manufacturing/scm and leveraging AI to improve business processes. The word “Yotta” in Yottaasys stands for the largest unit of data which can be measured

Media Contact

Company Name: Yottaasys

Contact Person: Arun Pandey

Email: Send Email

Phone: +918043707012

Address:#172, SIRI SKYLIGHT SECTOR 7, HSR LAYOUT

City: BANGALORE

Country: India

Website: http://yottaasys.ai